Translating Screw Jack

Main components of screw jacks are; trapezoidal lifting screw, worm screw, worm gear and gear housing.

The configuration of translating screw jacks differs from that of travelling nut screw jacks. In translating screw jacks, the trapezoidal lifting screw (also referred to as the lead screw) travels up and down through the gear housing. This linear motion is caused by the rotating bronze gear which is rotated by a worm shaft. The worm gear is threaded to accommodate the lifting screw thread. The gear housing provides a contained volume and mechanical support to hold the external forces applied on the lead screw and housing. The worm shaft can be turned by an electric motor or manually with a handwheel depending on the load, torque to be applied on the shaft and type of application.

As the worm gear rotates, the friction forces between the worm gear and screw thread act to turn the lifting screw also. The greater the lifting load on the screw jack, the greater the tendency of the lead screw to turn together with the worm gear. If the lead screw turns with the worm gear, it can not move linearly and it can not provide the desired force on the load. So, the load should be restrained from turning to achieve linear motion. If the application requires a free load and there is no possibility to prevent self turning, the design of the screw jack has to be changed and an anti-rotation mechanism should be used. The screw jack anti-rotation mechanism has a keyed lifting screw. The keyed design prevents the trapezoidal lifting screw to rotate around its axis and delivers linear motion.

Features:

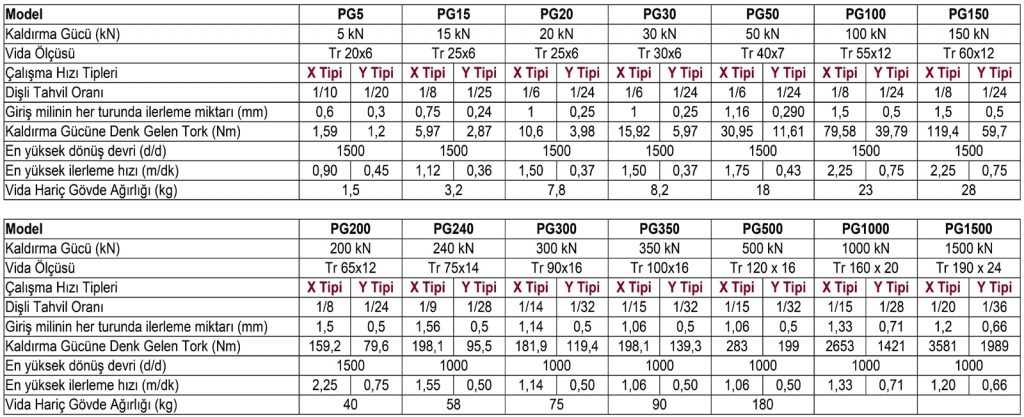

Please review the table below for more information on the requested capacity and dimensions.

For technical document of requested model, please use the button below. You may find technical drawings of the models on the opening page.

Please review the dimensions and technical data of screw jack models by clicking the buttons below.

Please review the catalogue and brochure of screw jacks by clicking the buttons below.

Wide range of screw jack systems are available in our production program. Please click on the configurator button below to create your screw jack.