Screw Jack

Screw Jack Working Principle

Screw Jacks are mechanical transmission devices used to convert rotational motion into linear motion for wide range of industrial applications. They incorporate a worm gearbox mechanism where an alloy steel worm rotates a high strength bronze worm gear. Rotation of worm gear causes a linear motion of lifting screw or traveling nut on the screw. Screw jacks enable linear motion solutions with precise positioning and smooth operation. They can be produced for load capacities between 5kN and 2000 kN. The linear motion speed and load capacity of lifting screw depends on the thread size, pitch and rotation ratio of worm gears.

Translating Screw

Main components of screw jacks are; trapezoidal lifting screw, worm screw, worm gear and gear housing. Worm screw is rotated manually or by motor. With the rotation of the worm gear, the trapezoidal screw inside the screw jack moves linearly upwards or downwards. If the trapezoidal screw tip is connected to a free load, the trapezoidal screw rotates circularly due to friction between the screw threads . So to have a linear only motion, the rotation of load is to be prevented mechanically.

Travelling Nut / Rotating Screw

Main components of travelling ball nut screw jacks are; trapezoidal lifting screw, worm screw, worm gear, lifting nut and gear housing. Worm screw is rotated manually or by motor. The lifting lead screw is fixed to the worm gear therefore the rotation of the worm gear causes rotation of lead screw about it’s axis. So the trapezoidal lead screw does not move up and down. The inside threaded bronze nut on the lifting screw moves linearly upwards or downwards. In travelling nut – rotating screw type screw jacks the trapezoidal screw does not go beyond the jack base. Thus, unlike travelling ball screw jacks, the gear housing could be installed on a flat surface.

Mechanical Screw Jack

Mechanical lifting and pulling jacks are used in industrial plants, ships, machinery assembly for lifting , pushing and pulling heavy loads and assembling large structures. Also known as journal jacks, mechanical screw jacks are produced as an alternative to hydraulic screw jacks. They can be operated at any orientation without any risk of oil leakage. The light and rigid body of mechanical journal jacks make them easy to use manually at every condition.

Screw Jacks

Screw Jack Types

Plain Head Screw Jack

Plain head type screw jacks are used in multi purpose applications. For free loads, linear motion is provided by the keyed lead screw option which makes a linear motion without unintended self rotation. The auto blocking system prevents the load from self sliding back.

Screw Jack With Top Flange

Top flange plated screw jacks offer linear mechanical movement and ease of installation due to properly sized top connection flange. The design of flange enables both push and pull applications for wide range of machineries.

Clevis End Screw Jack

A clevis end connection allows for quick and easy connection of screw jack lifting screw to other system components. Clevis joints are used to support linear thrust or tractive movements for different kind of mechanical applications. They are perfect fit for precise angular motion control applications.

Travelling Nut Screw Jack

Travelling ball nut screw jacks have a fixed length lead screw that rotates around it’s own axis. Load is attached to the traveling nut that translates linearly along the rotating screw. This type of jack is ideal for applications that require a flush mount on planar surfaces.

Screw Jack Types

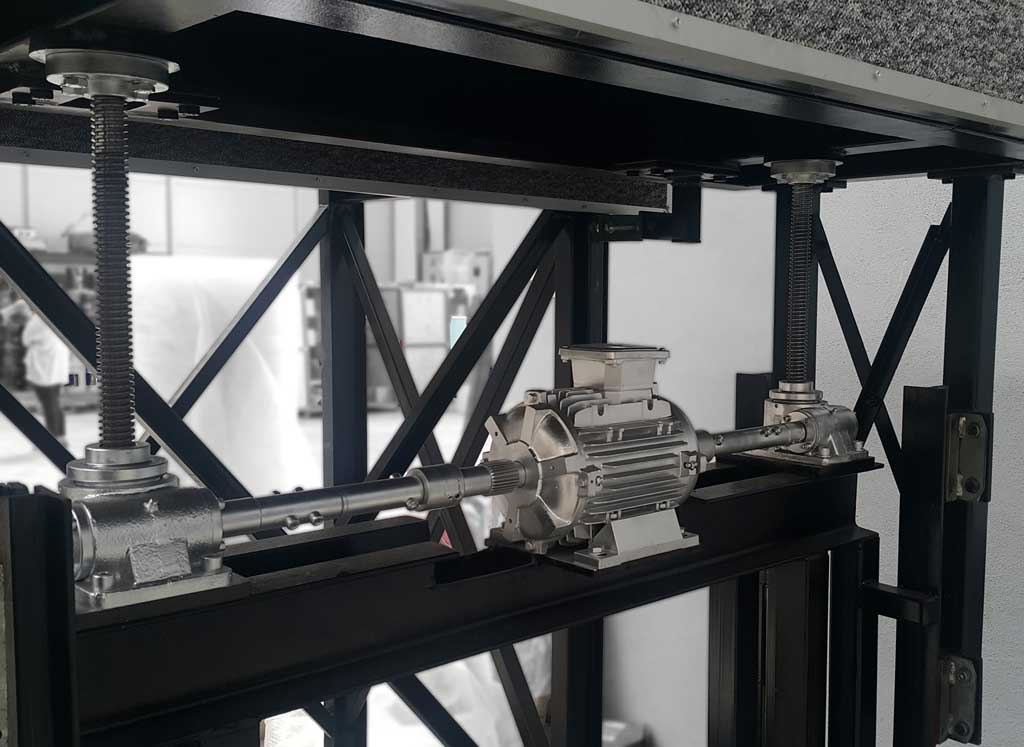

Screw Jack Assembly Examples

Benefit from our 40 years of experience

Having 40 years of experience on gearboxes and motion transmission systems with an unsurpassed dedication to quality, we provide state of art industrial equipment and systems for industrial facilities. Our expertise in linear motion systems enables us to provide solutions for wide range of applications. The standard range screw jacks provide proven performance for applications that are well known and commonly implemented. In addition, our custom engineering team has been executing custom product development and manufacturing for applications that require unique features.

Application Examples

Usage areas of screw jacks

Best solutions for linear motion

We serve companies around the world with years of experience to develop solutions for their applications and to provide competitive advantages in their business. Our highly qualified engineers, technicians, and project management team combine their disciplines and expertise to meet challenges in linear motion systems from a single component to turnkey installations. We work in close collaboration with our partners and customers starting from concept design to every stage of manufacturing process, offering solutions for most demanding industrial applications.

Screw Jacks FAQ

What is a screw jack?

A screw jack is a mechanical device that translates rotational motion into linear motion for a vast range of applications. The motion translation can either be vertical or horizontal.

What are the components of a screw jack?

A screw jack, also referred to as a jack screw, is typically made up of four fundamental components which are; a trapezoidal lifting screw (lead screw), worm screw (worm or input shaft), worm gear and a gear housing.

How does a screw jack work?

The main components of a screw jack play a fundamental role in how it works. As the worm gear rotates, the lead screw rotates about its axial axis and travels linearly upwards or downwards depending on the type of screw jack. This rotary motion of the worm gear is induced by turning the input shaft either manually or via an electric motor (especially for heavy-duty applications). When the worm screw starts rotating because of an externally introduced torque, its teeth pressed against the teeth of a worm gear cause the worm gear to rotate as well, thus initiating an upwards or downwards motion of the lead screw. The number of gear teeth, the screw pitch size and the turning speed determine the screw feed rate.

How are jack screws powered?

Jackscrews can be powered either manually using a hand crank, or electrically with a motor. In manual operations, a handle (hand crank) is attached to the end of the screw, allowing the operator to rotate it and move the lead screw up or down. Motorized jack screws, on the other hand, use an electric motor to rotate the screw. They offer faster and more convenient operation than manual jacks and can be programmed for precise positioning and movement. Some jack screws may be powered using hydraulics.

What is a screw jack used for?

A screw jack is among the various types of linear motion actuators that are typically used to raise or lower a load. They are commonly used in various industrial applications, such as lifting heavy machinery, adjusting the height of work platforms, and positioning large structures such as bridges and buildings.

Where are screw jacks used?

Screw jacks are used in various industrial and mechanical applications, where heavy loads need to be lifted, lowered or moved in a controlled and precise manner. Some common applications include:

- Lifting and lowering heavy machinery and equipment

- Positioning work platforms and lifts

- Adjusting the height of systems

- Moving large structures such as bridges and buildings

- Stabilizing and levelling machinery and structure

Screw jacks can be used in a wide range of industries, including automotive, construction, manufacturing, entertainment, communication, aerospace and many others.

What are the different types of screw jacks?

There are several types of screw jacks, including machine screw jacks (also known as worm gear screw jacks), ball screw jacks, and bevel gear screw jacks. Each type has its own advantages and disadvantages, depending on the specific application.

At Polimak we produce three types of screw jacks; (i) translating screw jack – trapezoidal lifting screw moves up and down through the gear housing in this design, (ii) travelling nut screw jack – the lead screw is secured to the worm gear and it turns due to the rotation of the worm gear in the design, and (iii) mechanical screw jack – this design is an alternative to hydraulic screw jacks.

What is the difference between a screw jack and a hydraulic jack?

Screw jacks and hydraulic jacks are both mechanical devices used to lift or lower heavy loads, but they work in different ways.

Screw jacks use a screw and threaded rod mechanism to lift or lower loads. They are typically slower than hydraulic jacks but can provide a higher mechanical advantage, making them suitable for use against very heavy loads with relatively little effort.

Hydraulic jacks, on the other hand, use hydraulic fluid to create pressure and move a piston, which in turn lifts or lowers the load. They are generally faster than screw jacks. Hydraulic jacks can also be more compact than screw jacks, making them suitable for applications where space is limited.

How much weight can a screw jack lift?

The amount of weight a screw jack can lift depends on its size and design. Screw jacks typically range in capacity from a few hundred kilograms to several tons. Larger screw jacks can lift much heavier loads, while smaller screw jacks are better suited for lighter loads.

Polimak’s screw jacks have a weight capacity range of a hundred kilograms (100 kg) to one-fifty tons (150 tons).Configure your screw jack.

Why Polimak's screw jacks?

With over four decades of experience, Polimak’s screw jacks are known for their reliability, durability, and customized solutions to meet the customer’s specific requirements. We offer a range of screw jacks with different load capacities, lifting speeds, and precision levels to suit various industrial needs.